The use of airlocks is often a theory that is definitely effectively-recognized in the look of cGMP amenities. Despite the evident simplicity of inserting small rooms in to the plan of a pharmaceutical producing facility, There is certainly confusion relating to their proper use and definition.

The controlled circumstances in gowning rooms, often controlled with HEPA filtration and beneficial airflow, make sure that contaminants from your exterior ecosystem do not enter the cleanroom.

To structure these an air lock a person need to consider that the quality of item should not get compromised when products cleaned, Decontaminated, Debagged & if the plant is operated repeatedly.

Contamination is actually a fermenter’s worst nightmare. The airlock functions as a guardian, trying to keep dangerous microorganisms and yeasts at bay. This not just makes sure the protection of the fermented greens but additionally contributes for the regularity with the fermentation method.

This gradient helps prevent contaminants from the considerably less clear location from flowing again into your cleaner parts. It truly is a super Alternative for standard contamination Manage in environments in which sterility isn't important.

-Interlocking system should be set up in airlocks to stop the opening of equally door simultaneously.

A cascade airlock operates on the basic principle of strain differentials, exactly where Each individual connected area has progressively reduced air strain as a single moves from a cleaner to some a lot less clean up region.

This is crucial because even little quantities of contamination can have really serious consequences, such as the creation of very low-excellent or unsafe merchandise.

While some swear by the simplicity of open jar fermentation, the potential risk of contamination is higher. Airlock-aided fermentation offers a more managed ecosystem, decreasing the chance of spoilage.

The sink airlock is especially more info useful in environments exactly where harmful resources, strong compounds, or biohazardous brokers are managed, as it helps make certain that any airborne contaminants or hazardous particles keep on being confined within the airlock or the significantly less cleanse zone, therefore defending both of those personnel and also the clean setting.

December one, 2024October 29, 2020 by Sajjad Ahmad Airlock system plays an essential position in pharmaceutical industries to guard clean rooms from contaminants and to circumvent cross-contamination. Given that the identify signifies, an airlock is actually a locking system that's produced by utilizing air strain.

one. Cleanliness Classifications: The airlock must be intended based on the cleanliness levels of the adjacent rooms.

An airlock is often a transitional Place Situated amongst two parts of differing cleanliness or containment stages. It is provided with doorways that cannot be opened simultaneously, sustaining managed problems in a single location though personnel types of airlock in pharma or resources are moved into One more.

This helps prevent to entry dust and contamination from exterior to airlock and from airlock to inner side.

Angus T. Jones Then & Now!

Angus T. Jones Then & Now! Michelle Pfeiffer Then & Now!

Michelle Pfeiffer Then & Now! Mason Reese Then & Now!

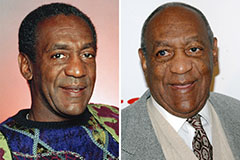

Mason Reese Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!